To intensify sunlight, we typically use thin glass mirrors, that have a silver coating on the back protected by paint, especially at the edges. In the 1970s, we

mounted individual flat mirror facets on aluminum tubes (see the photo below)

to make initial solar collectors. It took days to attach and orient 480 of

these facets on our first, a task that could only be done when the sun was shining,

since we used each mirror’s image on a target so each facet would reflect the center of its solar image to the same point.

Solar Collector: 1975 Student Competition on Relevant Engineering

A second generation mirror assembly, see photos below,

enabled mounting and aligning mirror facets in less than half the time but these

mirrors, and those of the prior approach were difficult to clean. Each mirror facet had to be polished individually.

Although the materials cost only a few dollars, these mirror assemblies had to

be put together on the job site because they were fragile, difficult to handle and

impossible to ship. Exposed mirror edges and corners too often tore clothing and skin and bumping a mirror usually required it to be realigned.

Adding Brackets to Hold Mirrors Reduced Assembly Time (1976)

To solve these glass mirror problems, we tried

substituting reflective aluminum sheet for the next solar collector. We formed

fiberglass bodies to hold reflectors that were easy for two people to handle

(at ten feet: ungainly for one person). These assemblies required special racks

for stacking and shipping. Although they had the proper parabolic shape along

the length, these mirror assemblies performed poorly because the aluminum

sheet that came rolled in a coil made the image of the sun too large. A

straightedge placed across the width of the aluminum showed that the reflective front was

convex, not flat or concave, even though we established an accurate concave

parabola along its length. This distorted sheet material elongated the image of

the sun, reducing sunlight concentration. It was easy to

squeegee clean the aluminum reflective surface but aluminum is softer than glass and easily scratched. After only months of use, the reflectivity of aluminum deteriorated, and when new it reflected significantly less sunlight than glass

mirrors that reflect over 90% of the sunlight.

Two Views of 1977 Solar Collector Showing 20 Aluminum Reflector Facets

Our next approach used the technology of a local swimming

pool company that had developed a pool structure made from panels formed out of

polystyrene foam with aluminum skins sandwiched between aluminum extrusions. We

worked with them to develop an ever-improving series of mirror assemblies that

began with bodies that had edges folded to form the sides and required separate

tabs to hold the mirrors. We then tried capturing mirrors with a feature on

curved aluminum side extrusions. Difficulty in sliding mirrors without breaking

any led to side extrusions that enabled any mirror to be installed or replaced

in less than a minute, see evolution in photos below.

Three Versions of Foam Core Mirror Assemblies

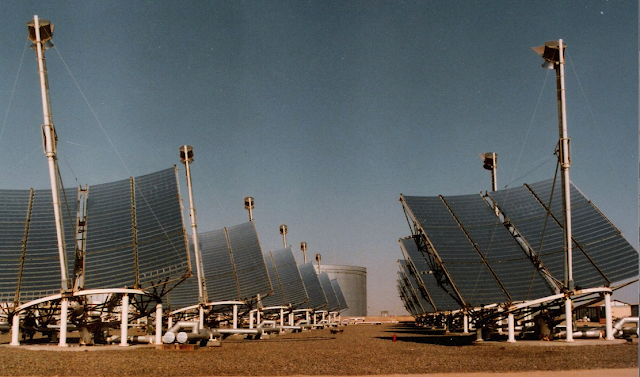

Eighteen solar collectors that we shipped to Saudi Arabia in

1982 for desalinating water from the Red Sea used the stainless steel screw/clip

version shown above. Each of these had 108 of these eight-foot long mirror

assemblies that could be stacked for shipping/staging and handled by one

person. Photos below show views of this project.

12 of 18 Solar Collectors on Red Sea, 1983

Solar Collector Showing Receiver With Alignment Target Above

Mirror Assemblies Turned to Enable Cleaning

These foam-core mirror assemblies fulfilled most of the

design features for early solar collectors but using flat, one-foot square

mirrors was not appropriate for making larger solar collectors that required

higher performance at lower cost. Newer industrial designs required larger

mirror facets that were curved along two axes to make them concave so that each

delivered an image of the sun that was much smaller than the mirror itself. Surplus

mirror assemblies from the early era made great raised beds for growing flowers

and vegetables, see below.

View Showing Two Versions of Foam Core Mirror Assembly Bodies Used to

Make Raised Flower Beds That Work Well After More Than 30 Years

These mirror assemblies firmly surrounded flat glass mirrors

and were easy to handle, store, and ship compactly. They were also easy to

clean and survived hail, frost and snow by facing the ground when not operating.

Because the image each mirror made at the opening of the receiver was larger

than the size of the mirror, a typical 864-mirror concentrator intensified

sunlight only about 500 times; good for producing low pressure steam but not

superheated steam above 60 atmospheres. For that we needed a concentrator that

delivered over 1,000 suns which requires accurately aligned concave mirrors,

the subject of the next installment, Mirror

Assemblies That Used Warped Glass Sealed Mirrors.